APPLICATIONS:

Heat shrinkable creepage extension sheds are used to increase the surface creepage distance of the protected cores of cable terminations without increasing the tail length. Heat Shrinkable strain relief sheds are used to restrict the cable cores from over bend-ing thus protecting from damage in the termi-nation near the crutch area. The creepage extension sheds and strain re-lief sheds are made from thermally stablized, cross linked, non-tracking weather polymeric material. These are coated internally with wa-ter resistant mastic..

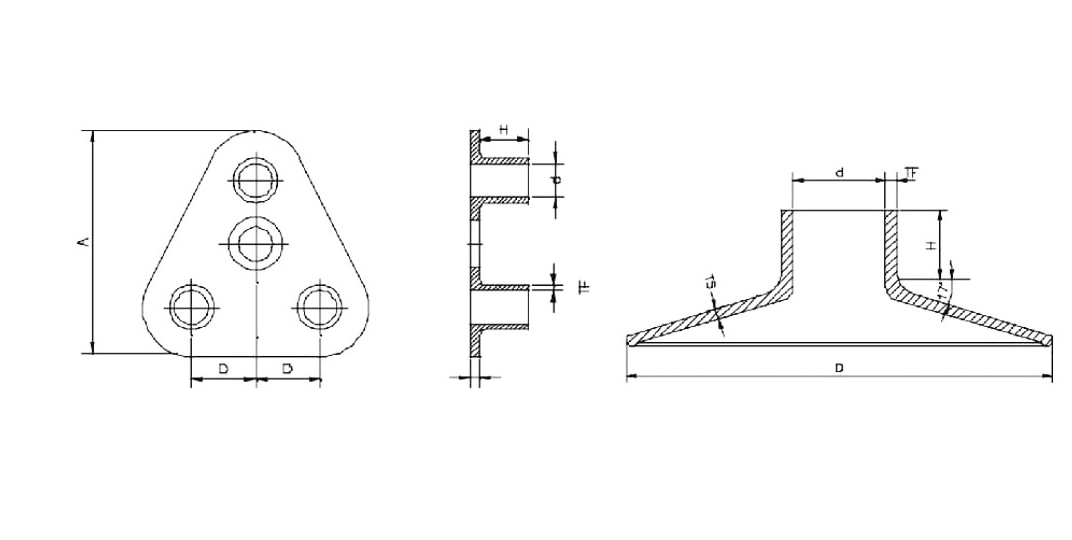

- All dimensions are in mm

- Drawing depicts typical dimensions E- As supplied

- S- After free recovery

- D,d - internal diameter without adhesive coating