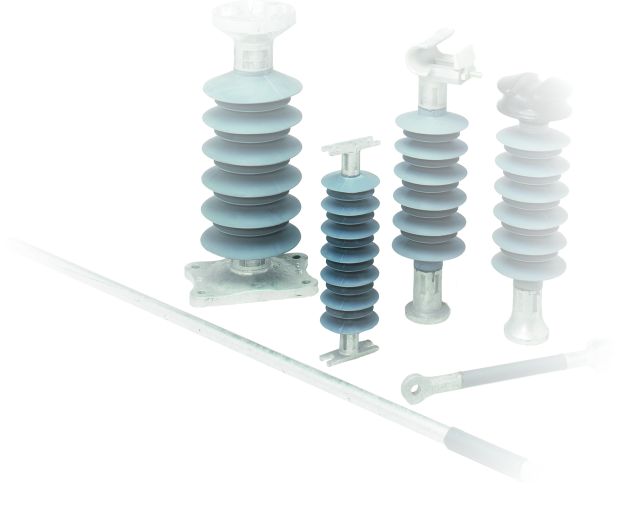

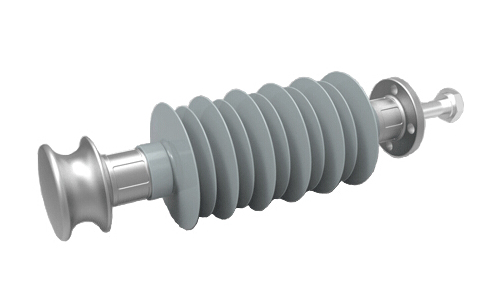

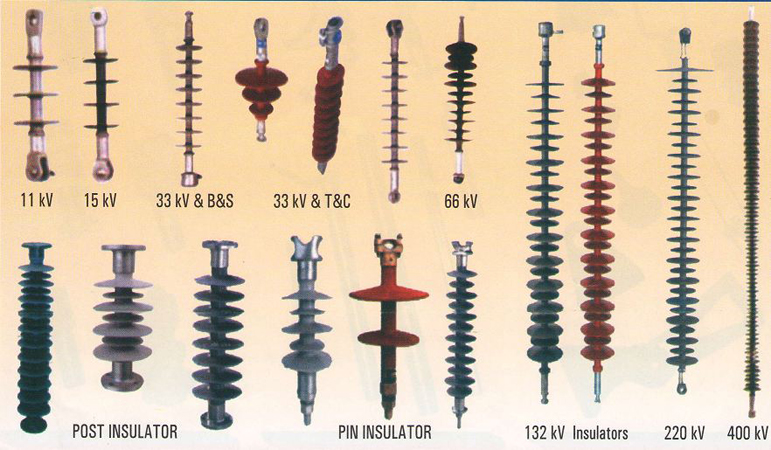

Type of Polymeric Insulator

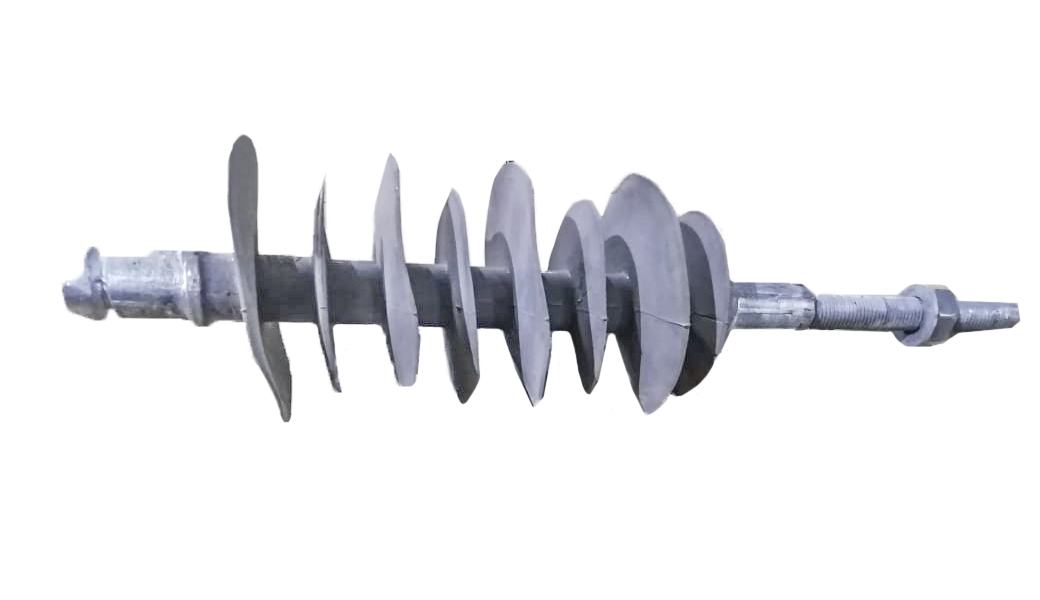

We work with high talented group, which is ace in planning, assembling and providing Insulators Tab. Our organization makes items that are high in quality and satisfies global quality guidelines. Our association has more than 4 many years of long standing knowledge and now one of the greatest fashioners, makers and providers of Insulators Tab, Cable Jointing Systems and Accessories,polymer composite separators and different other designing items. SGE is a standout amongst the best polymer composite protectors makers and providers in India. We work with high talented group, which is ace in structuring, assembling and providing Insulators Tab. Our organization makes items that are high in quality and satisfies global quality guidelines. Our association has more than 4 many years of long standing knowledge and now one of the greatest fashioners, makers and providers of Insulators Tab, Cable Jointing Systems and Accessories,polymer composite separators and different other designing items. Our association has more than 4 many years of long standing background and now one of the greatest originators, makers and providers of Insulators Tab, Cable Jointing Systems and Accessories,polymer composite covers and different other designing items.